hen the COVID-19 pandemic first hit in March 2020, Chris Shaver found himself temporarily laid off from his job as a welder at the Ekati diamond mine. With free time on his hands, he turned to growing microgreens—young seedlings of vegetables—as a hobby.

Two years on, Shaver and his partner, Nicolinea Minakis, are running a business, Northern Greens. Based out of Hay River, the couple have a 300-square-foot space their home property where they grow shelves of microgreens, using vertical farming techniques. Customers can place orders, which they receive on harvest days. Or they can subscribe to a service where, for $40 a month, Shaver and Minakis will deliver three varieties of plants each week.

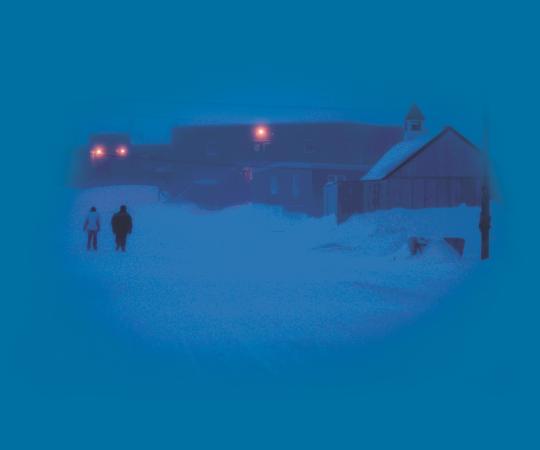

“Nicolinea and I love it, not only as a business, but as a nice hobby,” Shaver says, “especially in long winters in the North. We have our own little refuge in our grow room with the temperature and humidity controlled… it smells like summer in there with all our plants. It’s a morale boost for us just growing it, eating it for ourselves, and sharing with the community.”

Microgreens, which are flavourful and more nutrient dense than mature plants, have become a popular culinary trend in recent years. They grow quickly and are ready for harvest in just seven to 10 days (depending on the variety), when the plants are at the two-leaf stage. There are many types, including pea shoots, broccoli, radishes, and more.

Having grown up in a family of farmers and working as a farm hand, much of Shaver’s current business is second nature to him. But there are some big differences between monocrop agriculture on large plots of land and growing small plants in a modest indoor space.

With monocrop farming, the heavy lifting comes at the beginning of the growing season. After that, you essentially leave the crops on their own until it’s time to harvest. Microgreens, in contrast, don’t require as much brawn, but they do need careful management. “With controlled environment agriculture, we have to plant every Tuesday,” Shaver explains. “But before planting, we have to make sure everything is prepped and clean… Every day, we hand-water the plants and inspect every one. We harvest every week. It’s not as hard labour as mass monoculture [because you’re not using heavy equipment], but it’s a steady pace that never ends.”

That said, growing the plants is the easier part of running Northern Greens, Shaver says. “The most complicated part is the bureaucracy of everything, as far as growing the business. As well as the logistics and the health and safety paper work. But we keep on top of it all.”

In terms of laying the groundwork for Northern Greens, Shaver says he and Minakis spent two years on planning before they got their business licence and started sales. During that time, they were also buying equipment, working out the logistics of the business, and developing the business process.

The couple didn’t take out loans to start Northern Greens, so they’ve been able to launch without debt, Shaver adds. But the challenges keep coming as the business expands. Northern Greens has already moved into the Yellowknife market, offering local deliveries, and supplying the Woodyard Brew Pub, which features Northern Greens’ products on their menu. Shaver and Minakis made the six-hour drive from Hay River each weekend to serve customers in the

territorial capital but have been working on an agreement with Riverside Growers, another Hay River agriculture business, to take over deliveries.

The next step for Shaver and Minakis is introducing their business to smaller communities. They’ve already reached out to Deline and hope to set up Zoom workshops to teach other communities how to develop their own microgreen programs. “I think largely Northerners forget how good fresh produce tastes because we don’t have access to it,” Shaver says. “But when something tastes fresh, it isn’t comparable to something you get from the grocery store that has travelled thousands of kilometres or has been sitting in supermarkets for days or weeks at a time.”